Tuesday - July 24, 2012

continued……..

My College Years

Buena Vista College

Junior and Senior years of college 1961 to 1963

Note: There was a period of time between 1961 and 1963 that my mother and I founded our family business that lasted until 1980. I have decided that this would be a good place to insert the information, background and history of our family business. I must tell you it is a pretty long story. I tried to include everything I could remember about the forming and beginning parts of the story of the family business. Some of it you will find parts of it repetitious so please stay with me . Here it is:

The DaLe Story

1962 to 1980

There are some background stories that I need to tell you about how We (my mother and I) decided to form a partnership and call it DaLe Monogramming and Signs at the beginning.

Here it is:

Background History:

Mom’s background

Somewhere around the age of 8 or 9 another thing happened that gave mom momentum. Mom came home one afternoon after visiting Gil and Mary at the sewing machine shop next to the fire station all excited.

It seems that Gil had a new sewing machine that he showed to mom. She could not stop talking about how amazing it was and how many different things it was able to do. It was a Pfaff sewing machine.

I could tell that she wanted to have that machine to use in her lettering business. It didn’t take long until Gil made her the same offer that he did on the first machine.

She could pay him from the earnings she made on lettering. It was after she got the Pfaff machine that she was able to letter item like towels, shirts and make patches with the zigzag stitch that the Pfaff produced.

She continued to cut out the felt letters and apply them to the athletic uniforms but now she was also able to letter shirts.

The word got out and pretty soon she was also lettering shirts from some of the local clothing stores in Spencer.

I remember she did work for a store called Luthold and Crouse and another men’s clothing store call Hanson’s. Dad took one of the lettered uniforms to show the firemen at one of their monthly meetings and the firemen decided to have mom letter shirts with “Spencer Fire Department” on the back, with their individual names over the pocket of each shirt.

In September, I remember that Gill and Mary asked mom to work for them in their booth at the Spencer fair. She loved to do that. She would have a lot of people around her as she demonstrated all of the capabilities of this new zigzag sewing machine. She would demonstrate it durability by sewing through tin can lids and wooden yardsticks.

There was also another event that took place and she was involved in the initial Spencer Rodeo that was sponsored by the Spencer Chamber of Commerce. The chamber of commerce had her make special shirts that the members would wear prior to the rodeo. Webb, my cousin, and I also had shirts of the same design.

She continued lettering things of all kinds in the apartment at the fire station until it was decided that we would move to Sac City.

After our move to Sac City and Brother Tom was born, she started in sewing again in our home there is Sac City. I don’t remember when exactly this started, but it was after I was 13 years old.

helped start or worked for a man named Gordon Palm (I think that was his name). Art and Gordon had started the Spencer Reminder, a local shop

My background

My background basically started when I was in about 6th grade. Mom and dad had some good friends, Art & Blanch Woolsteincroft who had moved from Spencer to Minnesota. They had run a fishing lodge for a while then Art was offered a job as advertising manager of a business in Clara City, Minnesota, the Variety Supply Stores or V-Stores as they were referred to.

Art had, one time, when he was in Spencer had helped start or worked for a man named Gordon Palm (I think that was his name). Art and Gordon had started the Spencer Reminder, a local shopper newspaper. Art had skills in printing and art layout.

Jumping back to my USD & BV college years for a background reference

OK, now I will go to my freshman year of college. I was an art major and in the summer I had worked to help pay for my college expenses

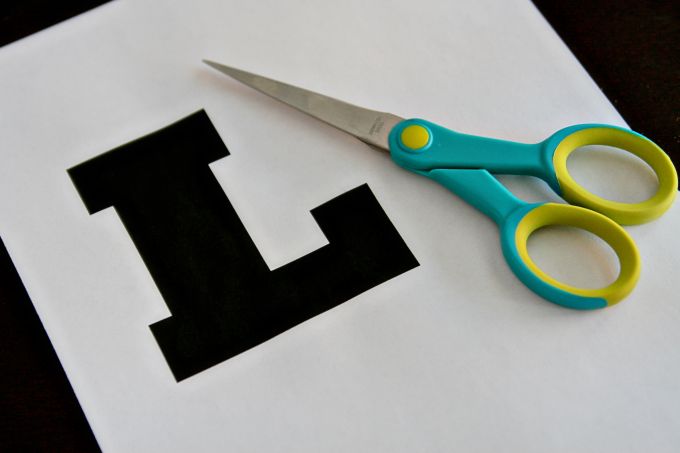

The summer between my freshman and sophomore year of college I was given the opportunity to do some sign painting. My dad was the president of the Sac City Little League Association and they had just installed a new fence in the outfield of the baseball diamond. There were 48 sheets of 4’ x 8’ sheets of plywood that had been painted white.Chain stitch lettering

A local sign painter named Buzz Corderman had been hired to paint signs on each 4 x 8 sheet of plywood. This was the way they paid for the fence, by selling sponsorship to Sac City businesses. Buzz was to get $5.00 for each sign. Well He painted one sign, got paid his $5 and with it, he would feed his favorite pastime, drinking wine. After painting one sign he disappeared and dad then made the suggestion to the board that I was an art major and had a skill at lettering.

My Sign Painting Business

I was then offered the job of painting the signs the 4 x 8 sheets of plywood. I did some investigating and discovered that a local paint store carried sign paint, brushes and other sign painting equipment that Buzz had used.

This started my sign-painting career in Sac City. I had just completed my first sign when one of my classmates father stopped, came over to me and said, “Dave, I didn’t know you painted signs!” I responded, “I just started!” Mr. John Lewis (Carmen Lewis Christiansen’s father) was his name and he was managing the local Ford dealership. He asked me to stop down to the building that housed the car dealership after I got done with the baseball sign I was painting.

I stopped and I still remember him taking me out in front of the `building and asking me to give him a bid on painting “Sac City Motor Company” in large letters (24 inch) on the front, then two large A-1 Used car signs on the side of the build needed touching up (It was almost unrecognizable).

I didn’t have a clue what to charge so I just figured that in the summers `before when I worked for a building contractor I had made about $36 a day. I calculated it would take me about 2 days to complete the job. The next day I went down to visit Mr. Lewis and said I would charge $75 plus he would pay for the paint.

Needless to say he jumped at my offer. So I now had the signs at the ballpark to work on, I was able to paint 3 or 4 a day after I got going and I was also working on the Ford dealership building. It war while I was working on the sign at the Ford dealership that a man from a stationary store business across the street came over and asked me to give him a bid on painting a sign on the front of his business.

It was like that from then on. I never had to advertise, the sign painting work just came to me. I also started painting a lot of lettering on trucks as well as building small road` signs.

DaLe’s Inception

It was then during the summer between my sophomore year and junior year of college at Buena Vista(1962) that Mom and I sat down for coffee one April morning. Decided to purchase a commercial chain stitch sewing machine.

I had just finished lettering on the side of a pick-up truck door and Mom had just finished lettering a set of uniforms sent to her by the Southerland, Iowa fire department in northwest Iowa. We decided to form the partnership.

The name DaLe came to us that same morning. “Da” from my name Dave and “Le” from her name Leah. I was going to be a junior in college at Buena Vista that next fall and I would be majoring in business management. I chose business management because I was hoping to use that formal training to aid in the development of DaLe. Originally we named the partnership DaLe Monogramming & Signs.

First Year of DaLe

The afternoon of the day when mom and I had decided to form a partnership and go into the lettering business, I jumped in the family car and started my survey. Every clothing store, sporting goods store that I called on was very happy to give us all their lettering business. Our local clothing store in Sac City we already were doing lots of shirt lettering. It was easy for them to order plain uniform shirts and let us do the lettering. This is the approach I took when I called on the clothing stores and the sporting goods stores in my survey.

I called on stores in the towns of Pocahontas, Carroll, Rockwell City, Manson, Storm Lake and Fort Dodge. Fort Dodge, Iowa was the largest town in the 50-mile radius.

These events happened before we purchased a commercial lettering machine. We were still using the Pfaff zigzag sewing machine to produce the lettering for the shirts and apply the felt letters that we cut out by hand to the athletic uniforms.

I can remember travelling in the family car each day to a couple of different towns. Each store I would call on I would introduce myself and explain what we were doing. 95% of the time I was received with a great deal of interest. My lack of selling experience seemed to be an advantage, I concluded later. I was not “hard sell” I was only sharing with them what we were doing.

We had developed a price list for the lettering that I would leave at each store with our address and phone number. For two weeks I made calls. Then I would return to the places that I had called on with more samples of our work. It was then that I started getting their attention and the stores would give me some shirts to letter. It was slow at first and the business from our local clothing store started to get larger.

Fort Dodge, Iowa was

a good Stepping Stone for DaLe

There are some events I now want to share about my visits to Fort Dodge. Fort Dodge, Iowa was the largest town in the 50-mile circle around Sac City. It was 45 miles straight east on highway 20. I started out calling on some of the clothing stores in Fort Dodge but ended up calling on a bowling supply store. The name was Styles Bowling Supply Company. There was a husband names Dwight and I forgot his wife’s name. I remember that they gave me an order of some bowling shirts to take home and letter. I was very excited about the first order.

I remember that I also called on a Regional Cooperative (Felco). I thought that Felco might potentially be a good customer. I talked to a man in their advertising department, Larry Nelson. Larry explained to me that they ordered their shirts from a larger uniform company that also produced and supplied them with their

sewn logo emblems. Little was I to know that about 3 or 4 years in the future I would be working for this regional cooperative, Felco. (I will be sharing that part of my life a little later.)

One other call I made was to a sporting goods store there in Fort Dodge, Kautsky’s. There was a man there that worked with the uniforms and I was able to show him samples of our lettering. I can’t remember all the things at the beginning of our association with Kautsky’s, but they ended up becoming one of our best customers in a fairly short time. I remember Mom and Dad both went over to talk to Jack there at the store one time.

A few weeks after I was able to start bringing in some lettering business we contacted Gil Gresslin up at the Spencer Sewing machine Company in Spencer and ask him to see about finding us the cost of a commercial lettering machine.

Not too long after that request, Gil got back to us and informed us that he had found a commercial chain stitch lettering machine. It was called a Cornely, (not sure of the spelling) it was a French made machine.

I Found this on a web site

about the Cornely Chain stitch

sewing machine……….

Originally produced by hand stitching, the production of chenille became industrialized about twenty years after the patenting of the lockstitch sewing machine. A French engineer named Bonnaz invented the first chenille sewing machine in 1866, soon he joined with the Cornely Company to manufacture and market his invention. A few years later Singer received the US Patent. Since the original machine very few design changes have been made. Some models added braid or cord, but the basic machine has remained the same for well over one hundred years. Today hand operated chenille machines are made by a number of machine manufacturers. These machines are widely used by skilled operators.

Gil informed us that the machine cost $600. Mom and I didn’t have $600 and I am not sure how it happened, but in a day or two, Dad had put his insurance policy up as collateral for a loan we made with the Sac City State Bank.

In just a couple of weeks, Gil arrived with our new French sewing machine complete with instructions in French! Gil had assembled the machine and was able to get us headed in the right direction to get it running.

Actually it was a pretty simple construction and with dad’s mechanical ability and Gil’s guidance we were able to make it run. It was totally different that running a conventional sewing machine.

The chain stitch machine was operated with a “crank” under the machine and pulled the material being sewed on along with a “claw foot”. Gil had explained that somewhere he learned that the position of the needle determined what kind of stitch was produced.

He told us the one we need was the chain stitch and he wasn’t sure what the chenille stitched was used for. (We would find out in the not too distant future, however.) We continued to use the Pfaff to letter as we experimented and learned to run the chain stitch machine. It took about 6 weeks to get the chain stitch machine operating and produce lettering the way we wanted it to.

One help that we received was the lead for a thread company that we could order our thread and supplied from out of Chicago. The name of the company was Troy Thread & Yarn Company and it is still in business in a very big way. I went to their web site and discovered how big they had gotten. www.troy-corp.com .

Now back to the chain stitch machine. I had gone and looked up and found information on the Cornely Chain stitch machine we had purchased and inserted it above.

We soon discovered that the Troy Thread and Yarn catalog we received was very helpful. It was from their catalog we discovered an easier way to mark the shirts with a way and a solvent and a felt dabber.

Also Troy was able to supply not only thread, but also felt and a product we experimented with and found very useful in our athletic uniform lettering, Tackle Twill. Tackle Twill was a satin-type finish with a rubberized backing. This rubberized backing allowed us to take the cut-out letters and numbers and iron them onto the uniform then sew around the edge of the letters and numbers much easier. We also noticed that they also sold yarn and felt and kept referring to various “Chenille” related products. We didn’t pay much attention to the chenille reference at first.

Our lettering business started to grow as we slowly converted over to lettering everything with the Cornely chain stitch machine. Soon we discovered we could use some additional help. Mom had a friend that showed an interest but said see had not done much sewing on and electric sewing machine. We discovered she was easier to train to run the chain stitch machine than someone who was already a good seamstress because she didn’t have to unlearn and relearn the different method of sewing required on the chain stitch machine.

DaLe’s First Employee

Floris Miller became our first employee. We set up our business in the basement of our home at 13th and Gishwiller in Sac City.

I would draw all the patterns, go out selling and paint signs, as I was able to get signs to paint. Since there were no other sign painters in the local area, most of my sign work came to me. I didn’t have to go out and drum up business for the sign painting.

I spent my junior year of college at Buena Vista College in Storm Lake, Iowa. I commuted with five others from Sac City and continued to work at building the lettering business at the same time I attended college.

Beginning of Chenille Letter Awards

The next major event I remember in the lettering business was when I decided to contact another Sporting Goods store in Fort Dodge. For reasons of not wanting to use a real name here, I will call the Sporting Goods Store Slogan’s Sporting Goods. One spring day I decided to call on Mr. Slogan at his Sporting Goods store.

I recall I had some samples of my uniform lettering all prepared to show him as I entered his store. I received a very cold welcome because I think he thought I was another “salesman”. He sensed right away I was really inexperienced at selling, I think.

As I attempted to show him my sample he acted very uninterested. As I was about to excuse myself, he whipped out a “Letter Award”. The letter “C” white with green felt trim

. He said, “Can you make these Chenille letters, as he tossed me the “C”?” Right away my mind quickly remembered the Troy catalog with all the chenille products and I said responding to his question, “Well, we are working at putting those kinds of things into our line” He said “well if you do you will really have something …come back when you are making them.”

I left with all the excitement of a baseball player that had just hit a homerun. I drove straight back to Sac City.

No comments:

Post a Comment